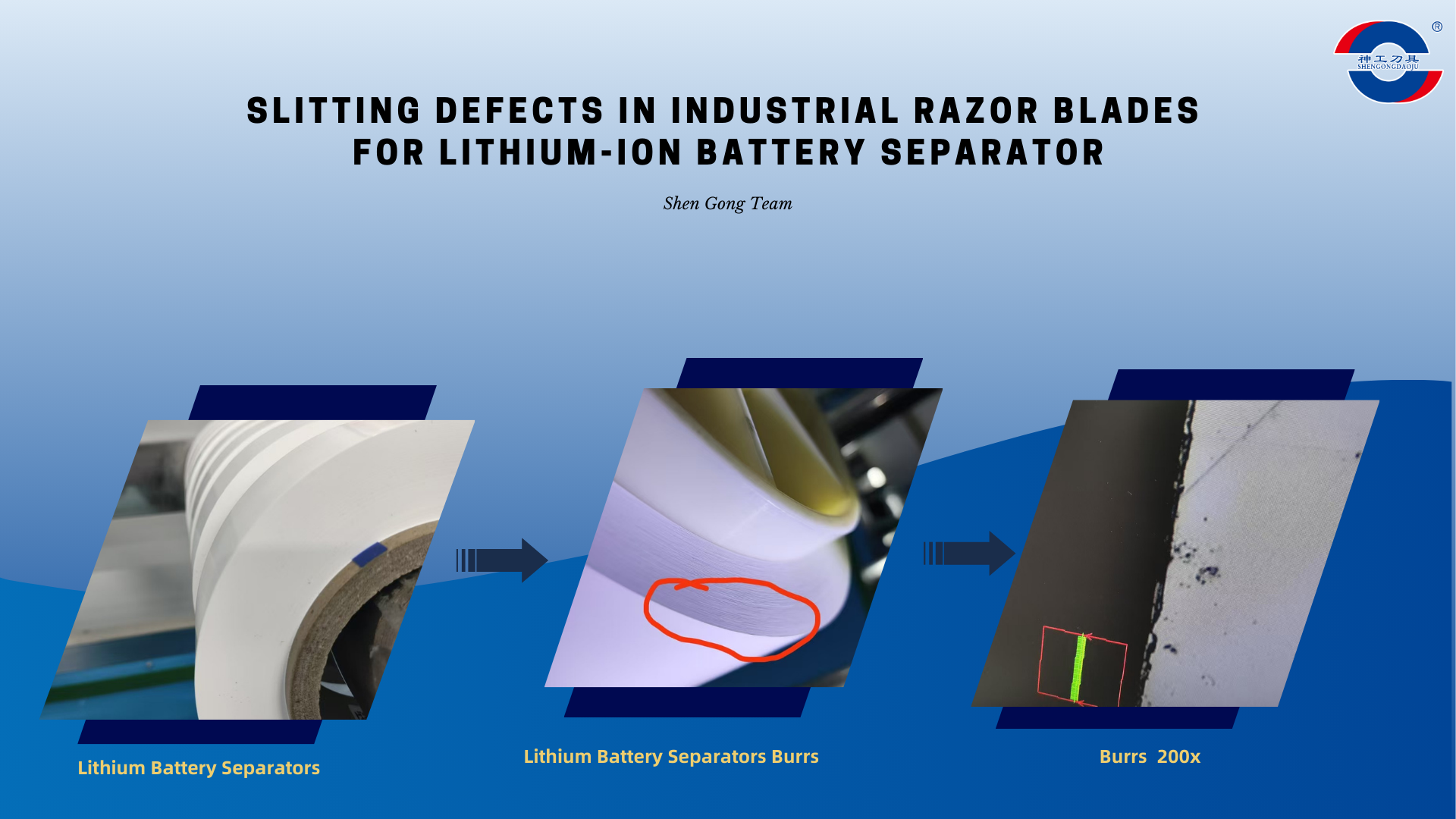

Industrial razor blades are critical tools for slitting lithium-ion battery separators, making sure the edges of the separator stay clean and smooth . Improper slitting can result in issues like burrs, fiber pulling, and wavy edges. The quality of the separator’s edge is important, as it directly affects the lifespan and safety of lithium batteries.

Understanding Lithium-ion Battery Separators

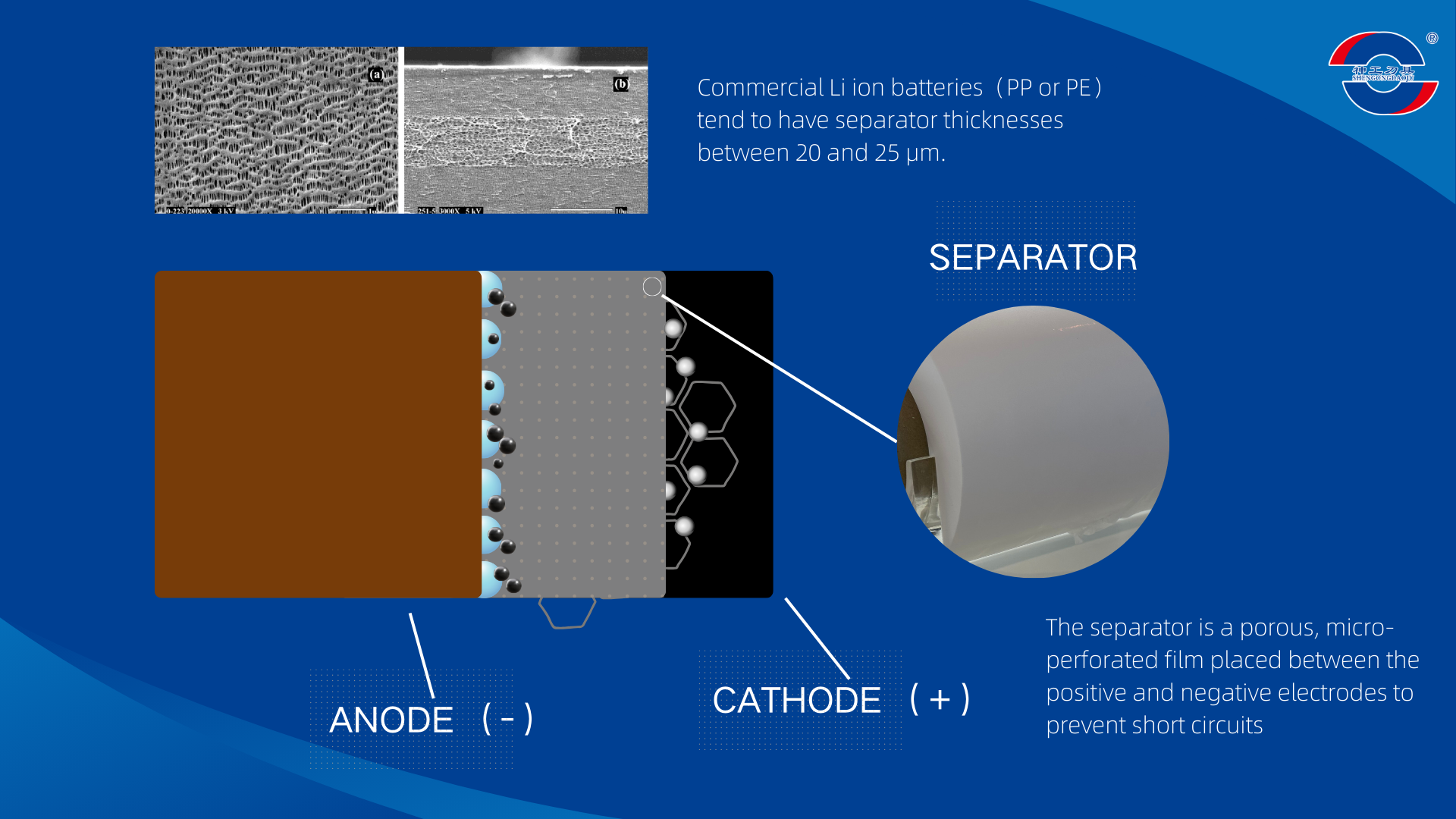

Lithium-ion batteries consist of several key components: positive and negative electrodes, electrolytes, and encapsulation materials. The separator is a porous, micro-perforated film placed between the positive and negative electrodes to prevent short circuits. It’s key to how well the battery works and how safe it is.

The main materials for lithium-ion battery separators are Polyethylene (PE) and Polypropylene (PP), both types of polyolefins. PE separators are manufactured using a wet process, while PP separators are produced through a dry process.

Key consider of Slitting Separators

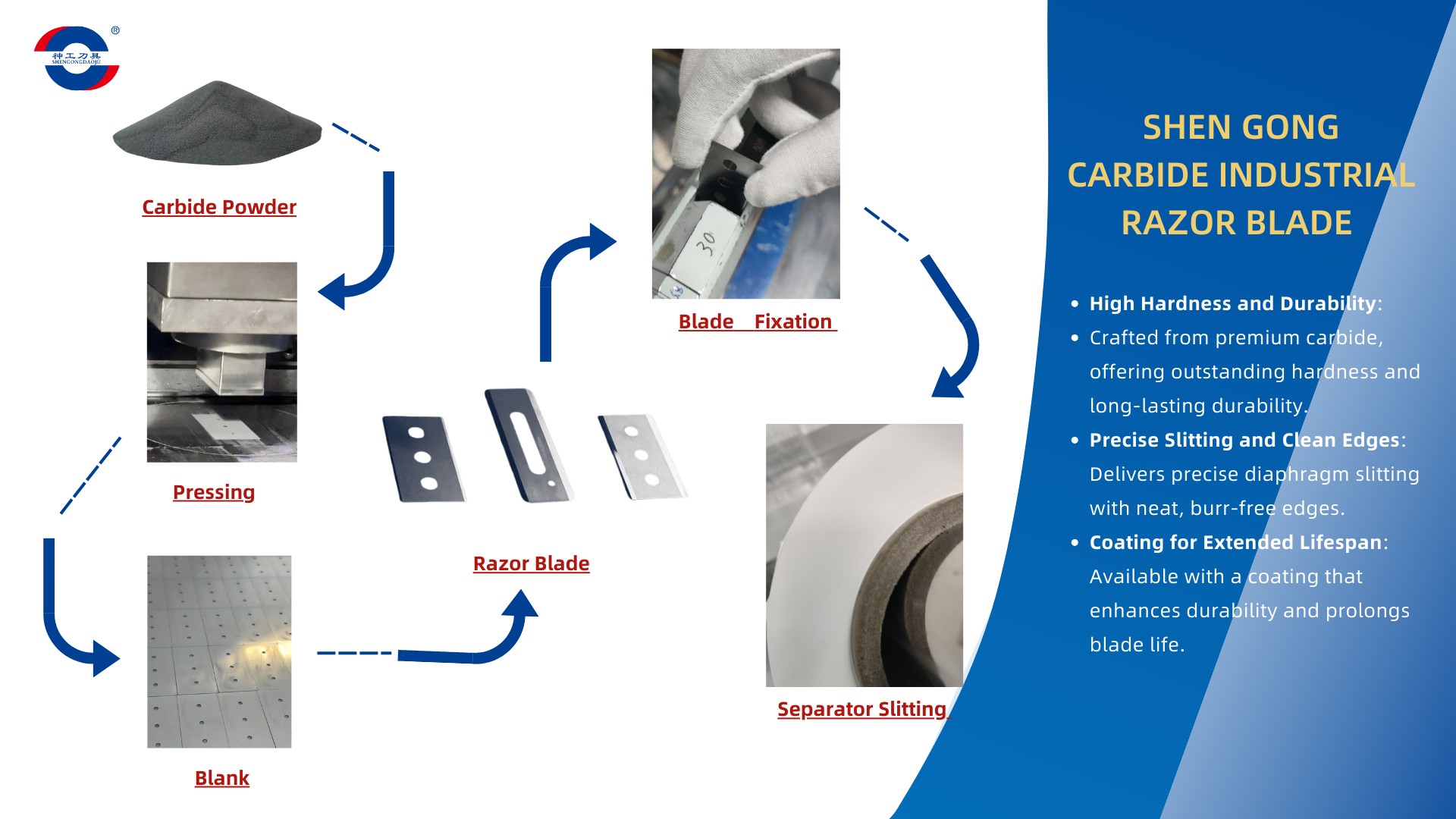

Before slitting, it is need to consider factors such as separator thickness, tensile strength, and elasticity. Besides, it’s important to pay attention to slitting speed and tension adjustments to achieve precision. Special conditions, such as wrinkles due to improper storage, must be addressed by flattening and static electricity treatments.

Whether it’s PE or PP separators, Shen Gong industrial blades are suitable for both materials. If you face slitting issues, choose Shen Gong industrial blades to ensure stable and efficient slitting performance.

More know-how of razor blades for Li-ion battery separator, please contact Shen Gong.

Post time: Jan-14-2025