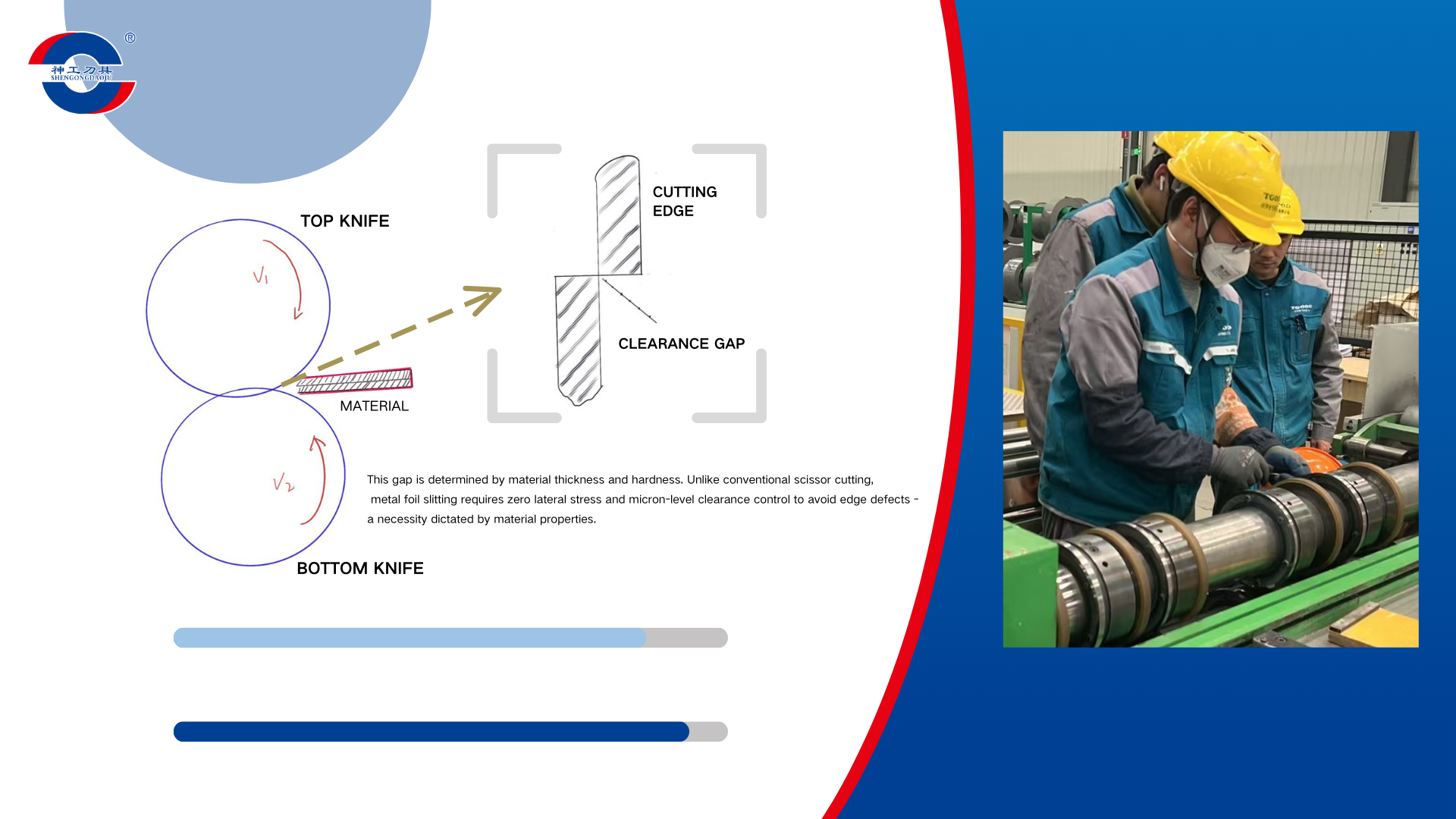

The clearance gap between TOP and BOTTOM rotary blades (90° edge angles) is critical for metal foil shearing. This gap is determined by material thickness and hardness. Unlike conventional scissor cutting, metal foil slitting requires zero lateral stress and micron-level clearance control to avoid edge defects - a necessity dictated by material properties.

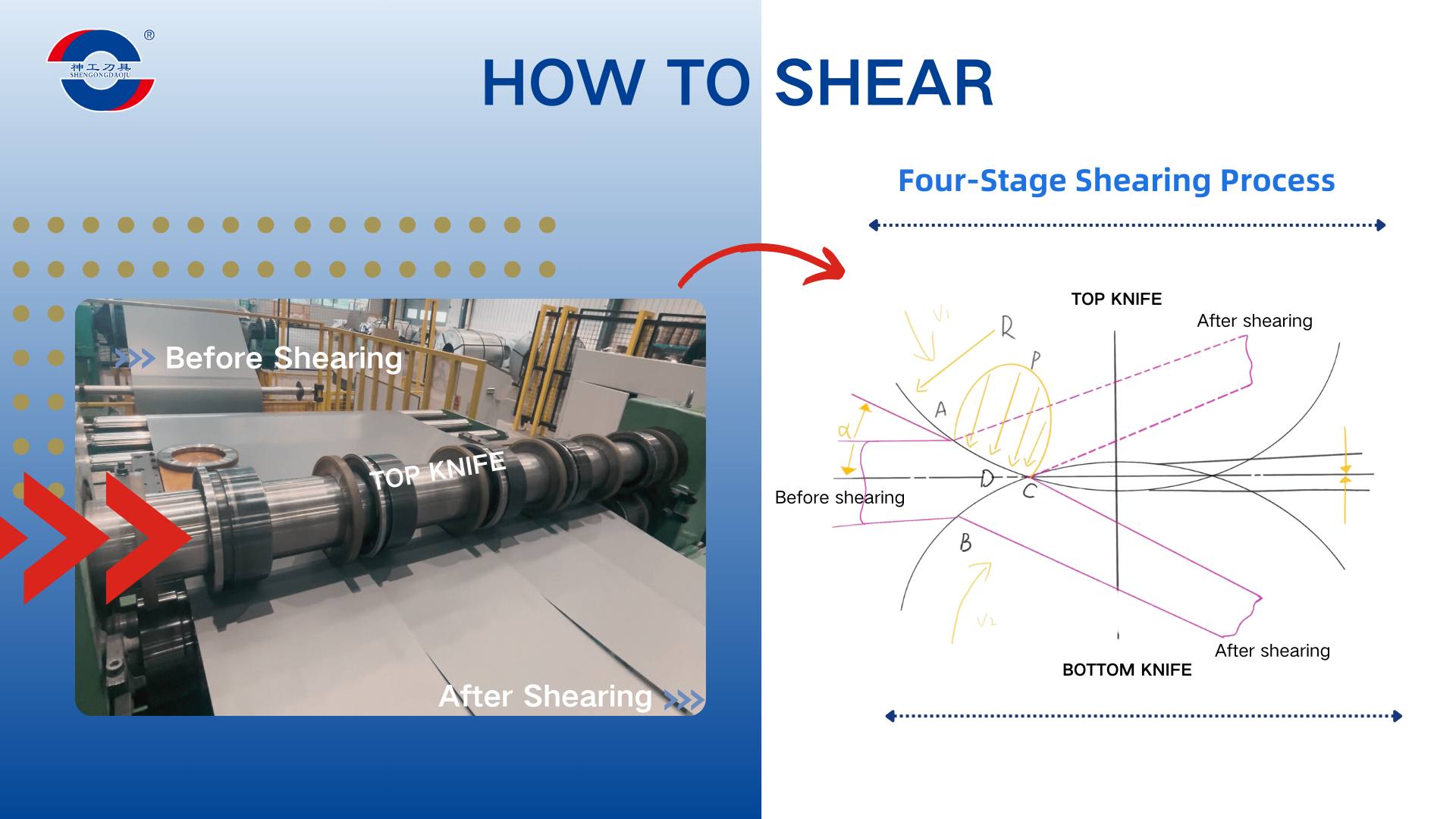

Four-Stage Shearing Process

1.Engagement Phase: Material enters through the blade overlap angle.

2.Deformation Phase: Controlled blade offset induces material distortion.

3.Slip Phase: Tension-driven material advancement creates controlled slippage.

4.Fracture Phase: Final separation through engineered tearing.

Why Controlled Fracture Matters

Pure compression cutting creates unacceptable edge defects. High-quality foil slitting demands:

Burr-free edges

Zero side bends/flanges

No compression marks

Optimal clearance adjustment produces a 1:2 shear-to-fracture ratio at 200-300X magnification:

Ideal Edge Profile: 33% clean shear layer fracture zone (7-9angle)

Overlap Warnings:

50/50 ratio indicates excessive overlap

<33% shear layer signals insufficient overlap

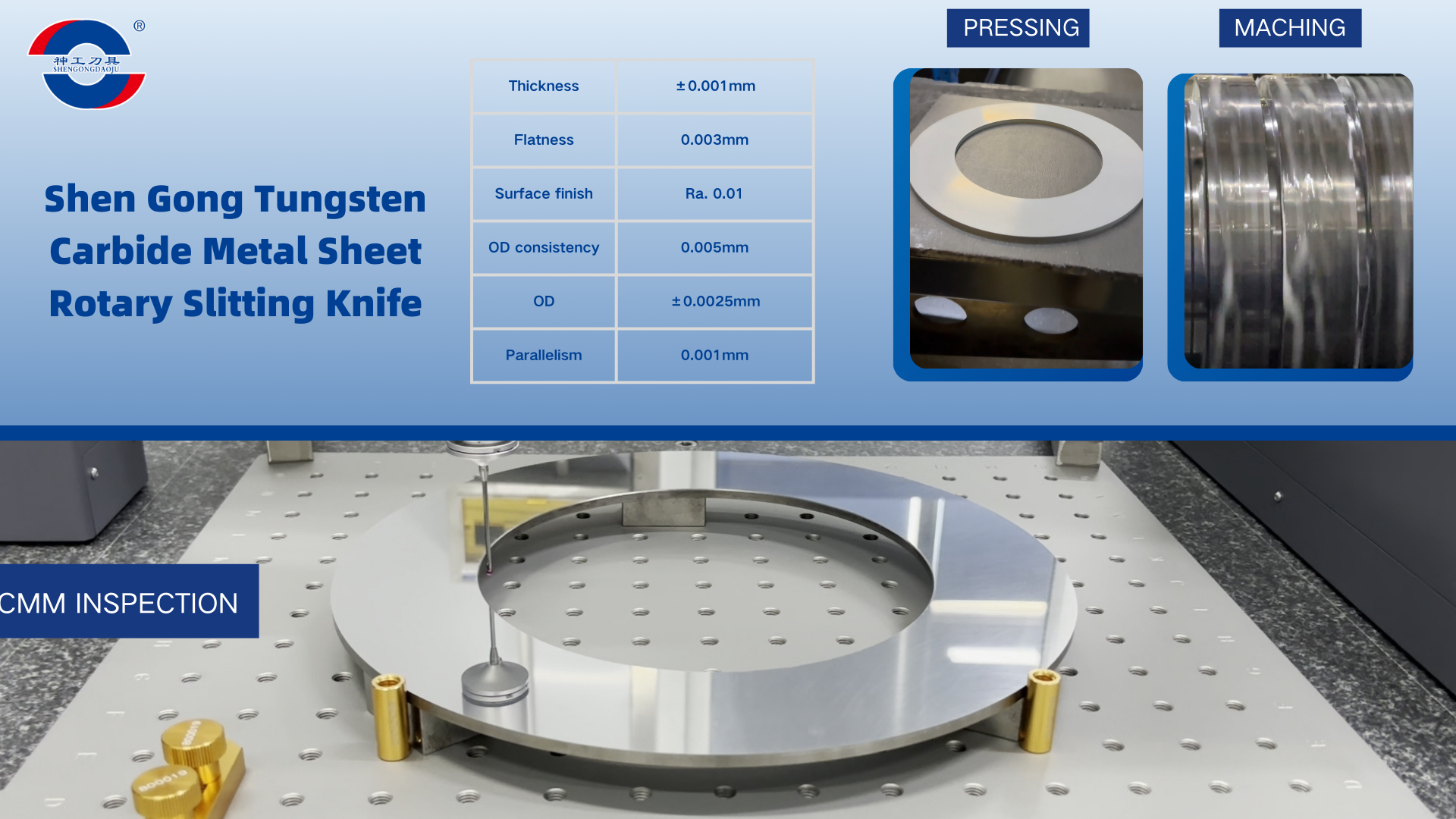

Shen Gong Tungsten Carbide Slitting Blades Excellence

Engineered for precision cutting of:Silicon steel/Nickel alloys/High-hardness metal coils

Performance Guarantees:Burr/flange-free edges at line speeds up to 800m/min

Ultra-precision tolerances:

Thickness: ±0.001mm

Flatness: 0.003mm

Surface finish: Ra. 0.01mm

OD : ±0.0025mm

OD consistency: 0.005mm

Parallelism:0.001mm

MAKE SHARP EDGE ALWAYS IN REACH

Optimize your metal foil slitting with ShenGong's ISO-certified rotary knives. To contact Shen Gong Team: howard@scshengong.com.

Post time: Feb-24-2025