In the corrugated production line of the packaging industry, both wet-end and dry-end equipment work together in the production process of corrugated cardboard. The key factors influencing the quality of corrugated cardboard primarily focus on the following three aspects:

Control of Moisture Content: Moisture content directly impacts the physical properties of cardboard, such as stiffness and compressive strength. Excessively high moisture content can make the cardboard soft, reducing its load-bearing capacity, while overly low moisture content can make it brittle, leading to easy breakage. Therefore, precise control of moisture content is one of the essential factors for ensuring the quality of the cardboard.

Temperature Control: The temperature parameters in the production process have a significant impact on the forming quality of the cardboard. Variations in temperature can affect the curing speed and effectiveness of the adhesive, as well as the properties of the paper fibers, which in turn can alter the structural strength and surface flatness of the cardboard. Thus, accurate temperature control is a necessary condition to maintain stable cardboard quality.

Slitting and Edge Quality: This factor directly determines the dimensional accuracy and edge condition of the cardboard, which is crucial for the precision and efficiency of subsequent packaging processes. Poor slitting quality can lead to packaging size deviations or edge damage, affecting the overall packaging quality of the product.

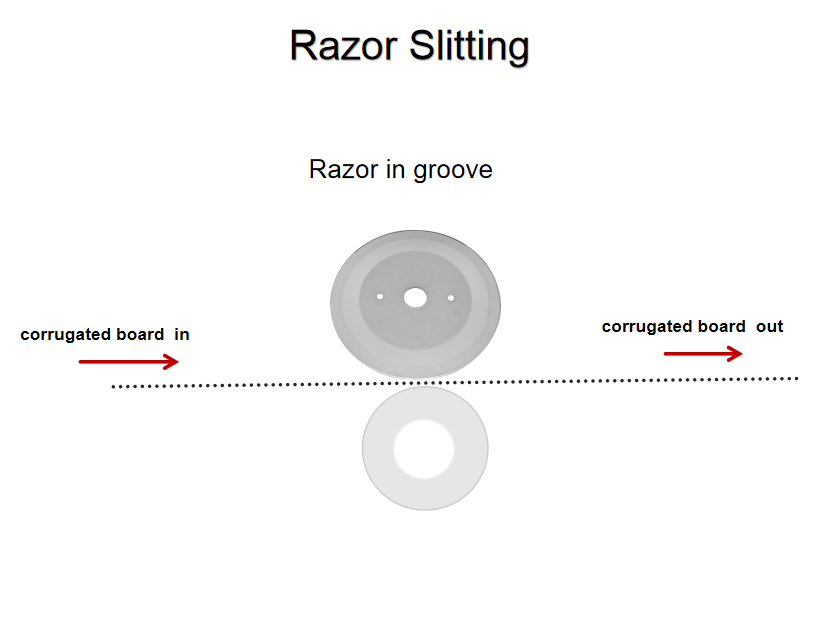

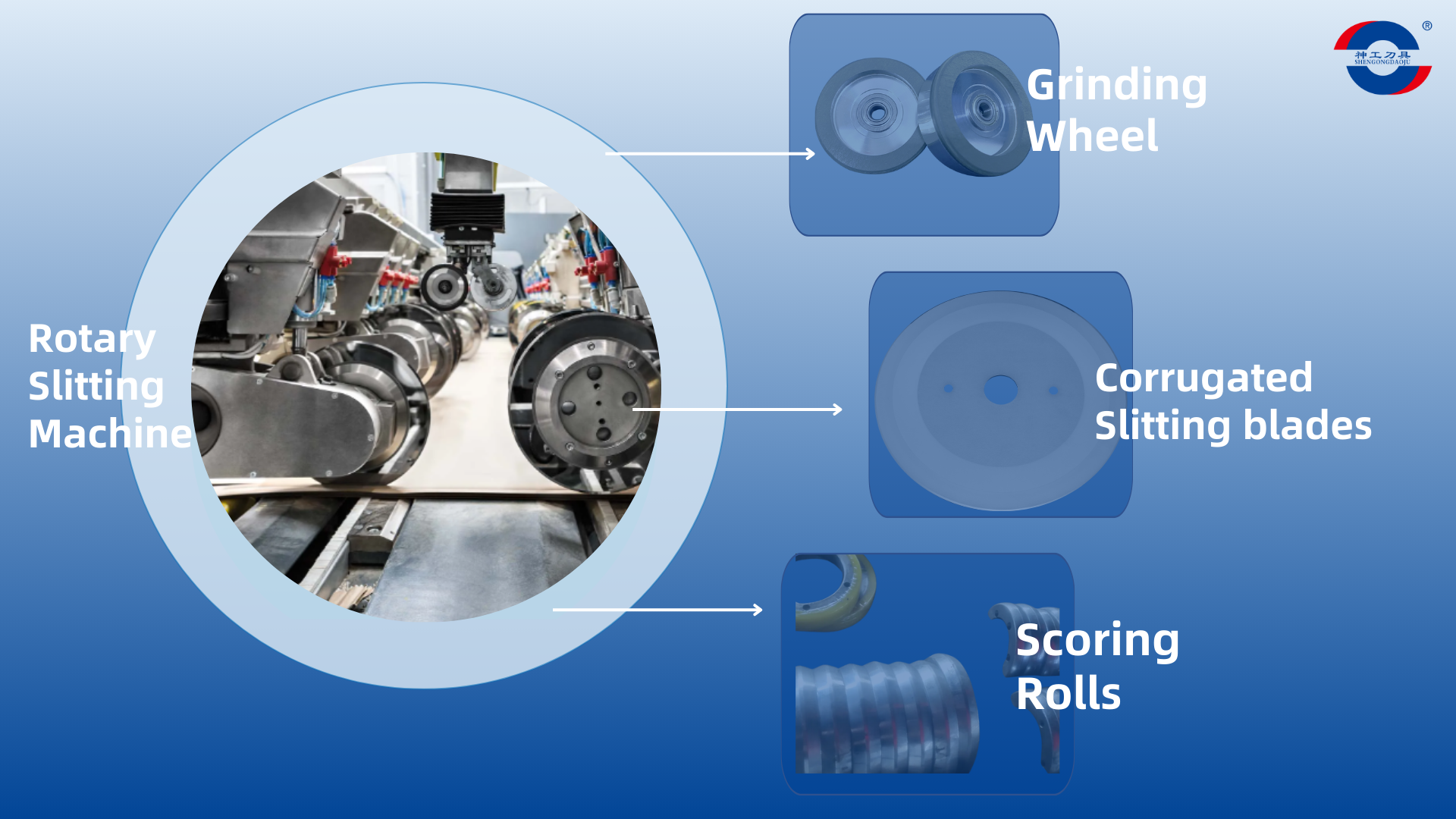

This article focuses on the slitting process.The corrugated board slitting machine consists of the following three core components:

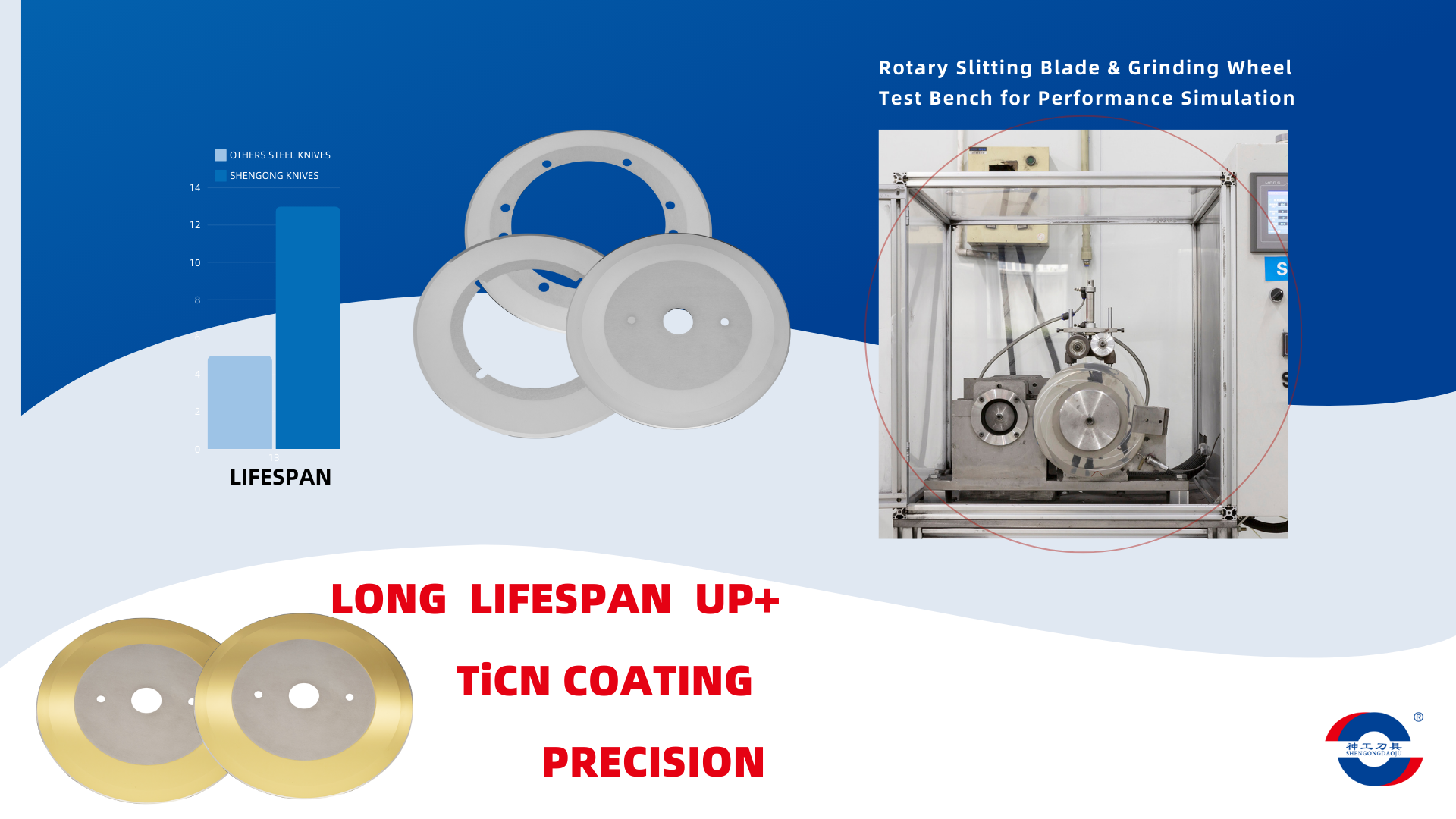

Corrugated slitter scorer knife: The slitter scorer knife produced by Shen Gong are made from high-quality tungsten carbide and binder materials, With thorough testing of materials and precise manufacturing processes. The outer diameter of the blades ranges from 200mm to 300mm, with thickness controlled between 1.0mm and 2.0mm. This precise dimension ensures that the blades generate the appropriate cutting force during high-speed rotation, resulting in high-quality slitting of the corrugated cardboard. During actual cutting, it ensures that the cardboard edges are smooth, without burrs or edge collapse, and prevents paper breakage.This meets the stringent quality requirements of the packaging industry.

Shen Gong has over 20 years of professional experience in the production of slitter scorer knife. We strictly control every stage, from raw material procurement to production processes and finished product inspection, ensuring that each rotary slitting blade meets high-quality standards and that We’ve got the production capacity to keep up with market demand.

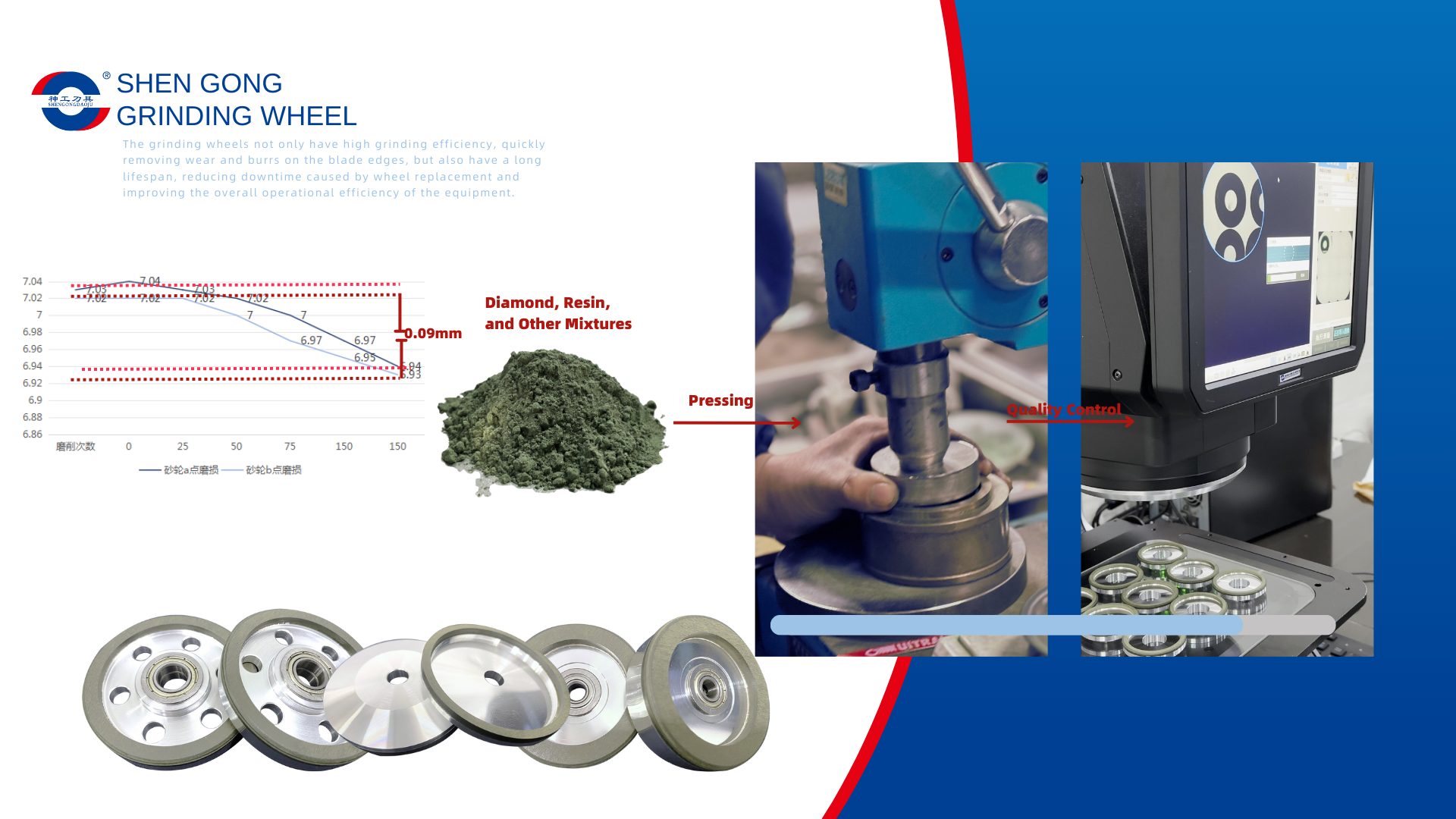

Grinding Wheel (Knife Sharpening Stone): The grinding wheel is key to keeping the slitter scorer blades sharp. The grinding wheels produced by Shen Gong are made from advanced grinding materials and manufacturing techniques.

They are paired in sets of two, working with wool felt for blade edge sharpening. The intelligent control system can set the sharpening program based on time or cutting meters, ensuring that the blades maintain excellent cutting performance throughout prolonged use. The grinding wheels not only have high grinding efficiency, quickly removing wear and burrs on the blade edges, but also have a long lifespan, reducing downtime caused by wheel replacement and improving the overall operational efficiency of the equipment.

Scoring Rolls: Scoring rolls are used to create precise crease lines on the corrugated cardboard, meeting the requirements for subsequent packaging folding operations.

Under normal production conditions, to ensure the quality of cardboard slitting, the knife speed is generally set slightly higher than the paperboard running speed, typically 20%-30% faster. This speed configuration effectively counteracts the stress generated during the cutting process, preventing issues like edge curling, thus ensuring smooth edges and dimensional accuracy of the cardboard, further enhancing the slitting quality and meeting the production requirements for high-quality corrugated cardboard in the packaging industry.

Shen Gong also provides comprehensive technical support for slitting blades used in packaging process. In practical knife, our technical team offers professional solutions and guidance for various issues encountered during blade usage, such as installation, maintenance, and performance optimization, helping customers solve production challenges, improve efficiency, enhance product quality, and reduce production costs and equipment failure rates.

Post time: Jan-04-2025