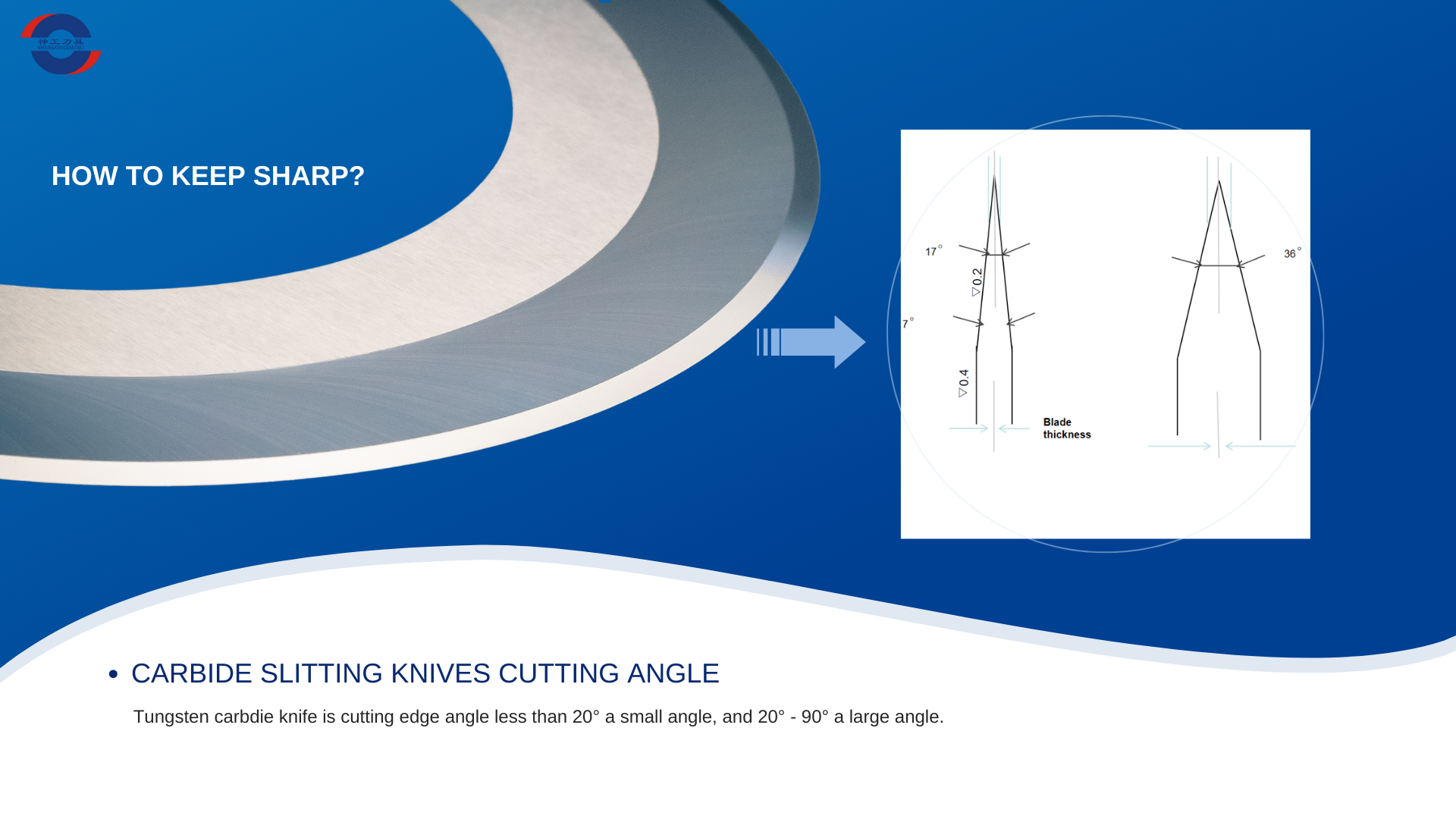

First, let's understand the cutting edge angle of the slitting blade:

Generally, we call the cutting edge angle less than 20° a small angle, and 20° - 90° a large angle.

A small angle is,a sharper blade edge, can easily cut into the material and is more suitable for relatively thin and soft materials, such as metal foils. However, after high - speed slitting with a sharp edge, the edge is prone to being dulled. For materials with higher hardness and thickness, the edge is likely to cause notches and blade breakage.

A large angle is a blunter blade edge. When slitting harder and thicker materials, the edge is stronger and more durable, and it is not easy to be damaged even under high pressure. The blunter edge of the slitting blade results in low precision of the cut material section and relatively low slitting efficiency.

During the specific processes of film slitting, corrugated board slitting, or metal foil slitting, we usually choose the cutting edge angle of the slitting blade according to the following factors of the processing environment and processing materials.

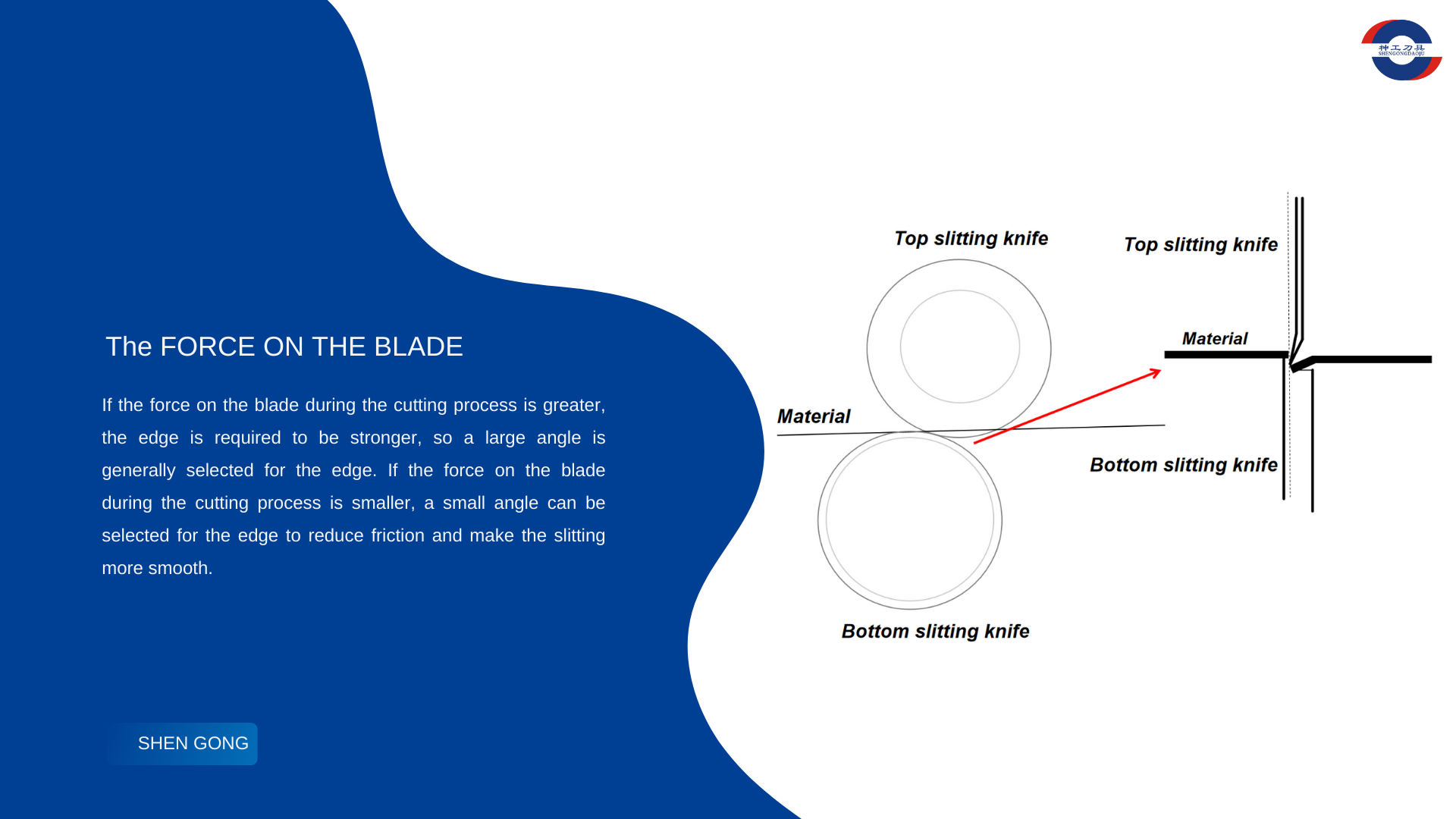

The force on the blade The thickness of the slitting material The hardness of the slitting materialIf the force on the blade during the cutting process is greater, the edge is required to be stronger, so a large angle is generally selected for the edge. If the force on the blade during the cutting process is smaller, a small angle can be selected for the edge to reduce friction and make the slitting more smooth.

When cutting thicker materials, it is recommended to choose a slitting edge with a large angle to provide better durability and toughness. When cutting thinner materials, a slitting edge with a small angle can be selected. The slitting is neat, not easy to be squeezed, and the slitting is accurate.

Of course, the hardness of the slitting material also needs to be considered.

Whether a smaller angle of the slitting knife is sharper and better depends on the specific application scenarios and materials.. If you need high - precision cutting and the material is not too hard, a smaller angle will be more appropriate. And if you are cutting harder materials, a larger angle will provide better durability.

In the slitting of soft materials such as corrugated boards, the sharpness of the tool is very important, but durability and maintenance also need to be considered. For such occasions, it is usually necessary to find a balance between sharpness and durability.

If you don't know how to choose the cutting edge angle of the tungsten steel slitting blade, you can consult Shen Gong team for free at howard@scshengong.com.

Post time: Mar-18-2025